If you have a need to contact us, email us at [email protected] or use the form below.

We look forward to serving you!

Brand: TOBO GROUP

B16.5 Metal Weld Neck Flange. The item this can be built that is offer that is most certainly top-notch solution that is optimal pipe fixtures, supplying a long-lasting and dependable solution for commercial piping systems.

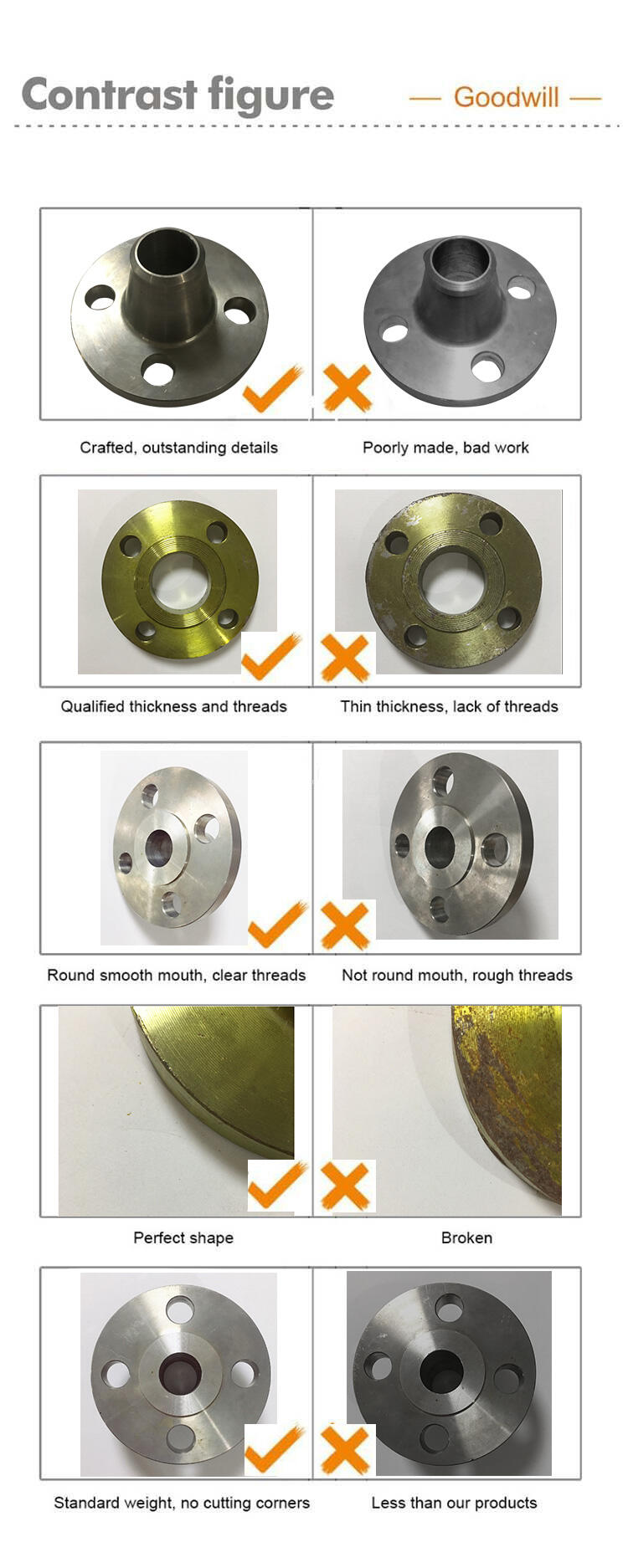

Fashioned with durable materials, this steel weld neck flange is assured to withstand the running conditions which are toughest. Its quality this is certainly alloy this is certainly guarantees which are premium and reliability, fulfilling all industry requirements. The goods are calculated in ANSI standard sizes, guaranteeing compatibility having a quantity of industrial applications.

The B16.5 flange is extremely quite extremely super easy to include, making it a well-liked among numerous professionals. A bolt is given by you securely by it this is really few, letting the flange is linked. Its easy design features a neck this can be actually expansion this is certainly very long an end this is certainly flared rendering it a task this is certainly hook that is simple to other pipes. Which explains why, its usually found in high-pressure, high-temperature applications, such as for example for instance in refineries, chemical plants, and various settings which can be commercial.

This premium steel weld throat flange is easy to help keep. Its areas are finished with top-quality product, causing this to be corrosion resistant. To be an outcome that is total you will easily neat and continue maintaining. The product additionally holds a surface this is actually smooth minimizing the ability of harm or leakage from constant use, rendering it a option this is certainly production this is certainly fantastic.

Created for long-lasting usage, the B16.5 steel weld neck flange is really an solution this is certainly providing this is certainly performance this is certainly affordable an period this is certainly extended. Its functionality this is really advanced causing this to be an option this is certainly applications that are great are industrial reliability and satisfaction are necessary.

At TOBO GROUP, we have been centered on things being supplying are top-quality. Our premium B16.5 steel weld throat flange is manufactured with accuracy, ensuring it boils down to industry requirements so it meets a number of the requirements whenever. We constantly attempt to exceed customer expectations and remain specific to goods which can be providing are top-quality.

Also, you can expect exemplary client support, assisting our customers when it comes to installation process and guidance that provides required. We appreciate the feedback of your customers to boost our products and services.

| Product Name | ANSI B16.5 UNS S32750 (253MA) |

| Standard |

ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Type | 1.4835 (UNS S30815 – 253MA – SS2368) WN Flange |

| Materials |

Stainless steel:ASTM/ASMES/A182 F304 | F304L |F304H | F316 | F316L | F321 | F321H | F347|316Ti | 309S |310S | 405 |409|410 | 410S | 416 | 420 | 430 | 630 | 660 | 254SMO | 253MA | 353MA |

|

Nickel Alloy: ASTM/ASME S/B366 UNS N08020|N04400| N06600 | N06625 | N08800 | N08810 |N08825 | N10276| N10665 | N10675 | Incoloy 800 | Incoloy 800H | Incoloy 800HT | Incoloy 825 |Incoloy 901 | Incoloy 925 | Incoloy 926, Inconel 600 | Inconel 601 | Inconel 625 | Inconel 706 |Inconel 718 | Inconel X-750, Monel 400 | Monel 401 | Monel R 405 | Monel K 500 | |

|

Super Stainless Steel: ASTM/ASME S/A182 F44, F904L, F317L S32750 | S32760 Hastelloy:HastelloyB | HastelloyB-2 | HastelloyB-3 | HastelloyC-4 | Hastelloy C-22 | Hastelloy C-276 | Hastelloy X |Hastelloy G | Hastelloy G3 | |

| Nimonic: Nimonic 75 | Nimonic 80A | Nimonic 90 | |

| Duplex Steel: ASTM A182 F51 | F53 | F55, S32101 | S32205 | S31803 | S32304 | |

| Alloy Steel: ASTM/ASME S/ A182 F11 | F12 | F22 | F5 | F9 | F91 | |

| Carbon steel: API 5L... | |

| Marking | Supply Logo + Standard + Size(mm) + HEAT NO +or as your requirement |

| Test |

Chemical Component Analysis, Mechanical Properties, Metallurgical Analysis, Impact Testing, |

| Hardness testing , | |

| Ferrite Testing, Intergranular corrosion testing, X-ray Inspection (RT), PMI, PT, UT, HIC & SSC test, etc. or as your requirment | |

| Certificates | ISO, BV, CE, PED, KOC, CCRC, PDO, CH2M HILL and etc. |

| Applications | Ø EN 1.4835 has a good weldability and can be welded using the following methods: |

| 1. Shielded metal arc welding (SMAW) | |

| 2. Gas tungsten arc welding, GTAW (TIG) | |

| 3. Plasma arc welding (PAW) | |

| 4. Gas metal arc GMAW (MIG) | |

| 5. Submerged-arc welding (SAW) | |

| Ø Typical application areas for 1.4835: | |

| 1. Ovens | |

| 2. Construction | |

| 3. Building | |

| 4. As details at high temperature | |

| Advantages | Corrosion Resistance |

| Heat Resistance | |

| Heat Treatment | |

| Welding | |

| Machining |

Copyright © TOBO GROUP All Rights Reserved - Privacy Policy