If you have a need to contact us, email us at [email protected] or use the form below.

We look forward to serving you!

Introduction:

Steel tubing elbows are an essential component the development of numerous structures, from simple furniture to massive buildings, like ss elbow created by TOBO GROUP. They come in various sizes and shapes, creating them versatile and easy to include.

Steel tubing elbows, including weldable elbows by TOBO GROUP offering several benefits other materials. Firstly, steel is merely a challenging and materials which was durable can withstand heavy loads and harsh conditions. Its also resistant to corrosion, rust, and fire, making it an ideal choice outside structures. Next, steel tubing elbows are lightweight and simple to move and make use of, which decreases construction work and time costs. Finally, steel try an environmentally material friendly are recycled, reducing waste and conserving natural resources.

The steel tubing industry is constantly innovating, and tubing elbows isn't any exception. New manufacturing techniques materials used to produce more powerful, more flexible, and corrosion-resistant elbows. As an example, some steel tubing elbows, same with 180 degree pipe elbow produced by TOBO GROUP are designed to withstand high-pressure use numerous companies, such as gas and oil. Other individuals are covered with special coatings that prevent rust and improve the durability of the elbows.

Using steel tubing elbows, also the galvanized steel pipe elbow by TOBO GROUP safely is essential to avoid accidents and homes harm. Always put protective gear such as gloves, protection glasses, and shoes, when handling steel tubing elbows. Before installation, make sure that the elbows is free and clean each and every defects, such as cracks or dents, which could weaken their structural integrity. Proceed with the manufacturer's instructions regarding installation use, and never meet or exceed the utmost load capacity of the elbows.

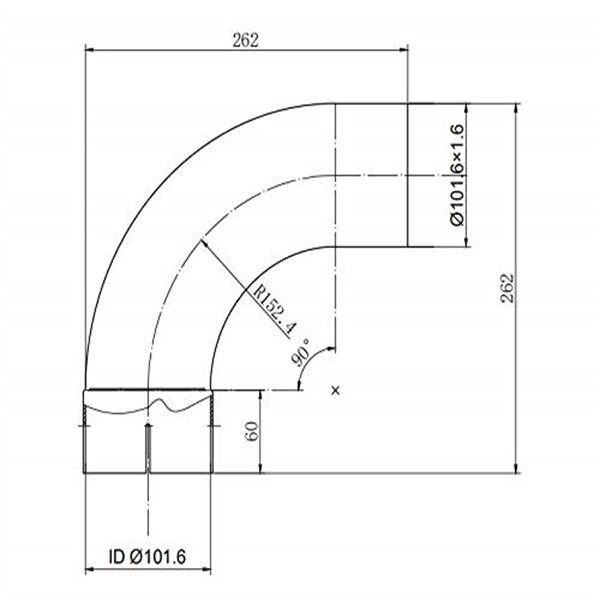

Steel tubing elbows need many uses that could be practical construction and manufacturing, just like the 90 degree steel pipe elbow built by TOBO GROUP. They've been commonly found in the production of furniture, play ground equipment, handrails, and safety barriers. In commercial settings, steel tubing elbows are used within the construction of piping systems in various industries, such as gas and oil, chemical production, and wastewater treatment.

main focus is making nickel-based alloys, as well as titanium alloys. This includes reducers, flanges, tees various other products for Steel tubing elbowsuse. Importers are vital for us in the steel industry. We're dedicated ensuring the quality of our products, to helping customers find right product. Our rich product range ensures you will find the best solution your needs whether it's manufacturing, construction, oil gas sector, or in any other field.

company has provided high-quality Steel tubing elbowsmade of steel metal products to the country's construction industry, particularly engineering projects.As an organization with modern production equipment as well as rigorous quality control process, we're in a position to guarantee the reliability long-lasting nature of our products and satisfy the requirements for all aspects of construction work.

can provide custom solutions to ensure that the materials made steel will be precisely Steel tubing elbowsto your requirements. doesn't matter if it's custom measurements coatings that are specialized, or certifications specific your project we will collaborate with you provide steel materials that compatible with your specific project's requirements.

Importing from China a challenging task for new importers. TOBO considers it a priority these importers, particularly in the steel industry. We aid customers in finding the best suppliers, guarantee that the product is high quality and schedule delivery to the port, Steel tubing elbowsentire procurement process easier and safer.

Using steel tubing elbows was relatively easy, as well as the 1 inch 90 degree elbow steel by TOBO GROUP, even for people who are not handy with tools. Here is one step by step guide on how best to use steel tubing elbows:

1. Gauge the length concerning the metal tubing you need and mark it with a marker.

2. Cut the metal tubing at the marked line with a hacksaw or metal cutting tool.

3. Insert one end related to metal tubing into the steel tubing elbow.

4. Adjust the angle of the elbow until it reaches the required position.

5. Repeat steps 1 to 4 for one other end regarding the metal tubing.

6. Secure the elbows set up screws and that can be using bolts (if required).

When purchasing steel tubing elbows, identical to weld 90 degree elbow supplied by TOBO GROUP, its essential to go for a reputable supplier that offer high-quality products and customer exceptional service. A good provider provide you with technical help, product advice, and after-sales services. They're going to also provides a wide mixture that meet up with the specific needs budget.

This product quality of steel tubing elbows, along with the 90 degree steel tube elbow by TOBO GROUP are crucial for their protection and durability. Low-quality elbows can result on structural failures that could causes property damage and on occasion even injuries. To ensure that you get high-quality steel tubing elbows, select a supplier who make usage of high-grade steel, advanced manufacturing techniques, and rigorous quality control procedures. Try to find certifications, such as ISO 9001, which indicate that the provider adheres to strict quality.

Copyright © TOBO GROUP All Rights Reserved - Privacy Policy