If you have a need to contact us, email us at [email protected] or use the form below.

We look forward to serving you!

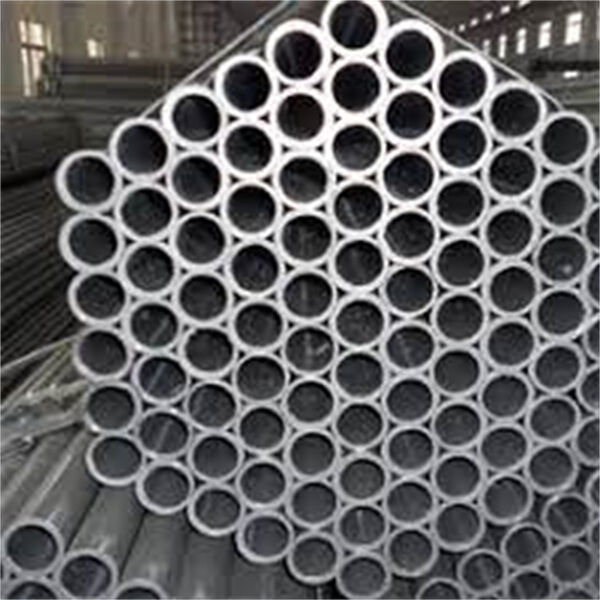

To locate a strong and durable steel can withstand extreme conditions? look no other further than TOBO GROUP super duplex pipe. This innovative metal many importance and is getting increasingly popular in a variety of industries.

Alloy 690 tube is well-known for its high opposition to and oxidation, making it an ideal choice application in harsh environments. TOBO GROUP aluminum pipe flange would likely withstand high pressure temperatures up to 700°C, rendering it an excellent option use within the petrochemical and aerospace industries. Another significant benefit its high strength and toughness, providing excellent protection against impact and wear.

Alloy 690 tube is an innovative metal has been developed by mixing many different elements to achieve its unique properties. This TOBO GROUP brass threaded nipple was consisting of nickel, chromium, iron, and molybdenum, among other elements. The blend of these elements renders for a metal that was highly resistant to corrosion and oxidation, with excellent strength and toughness. This innovation has resulted in quickly an alloy becoming the go-to selection for many industries.

Safety is vital when coping with any steel. Fortunately, TOBO GROUP reducing nipple female is a safe metal assist as it doesn't release harmful gases or chemicals. Additionally, its high resistance to and oxidation means that it won't break down or rust with time, increasing their overall safety.

Alloy 690 tube has many practical uses from the aerospace and petrochemical companies to power generation and chemical processing. Its high strength and to corrosion allow it to be a perfect option the number of applications. TOBO GROUP elbow galvanis 4 inch is commonly found in heat exchangers, boilers, and steam generators due to its capability to withstand high pressure conditions.

have provided our company's engineering industry with high-quality metal steel Alloy 690 tube. With modern production equipment and an extensive quality control, business can ensure the durability reliability its products.

provide customized solutions to make sure that steel materials you get are exactly Alloy 690 tube your specifications. We will work with you develop custom sizes, special coatings certifications to ensure that the steel materials we offer meet requirements of your particular project.

We specialize producing the nickel-based alloys as well as titanium alloy Alloy 690 tube, including reducers, flanges, Tees, various other thermal products. value importers of steel. Our goal is to help customers find right product and ensuring product quality. vast product line guarantees you will find the best solution your needs regardless of whether you are in manufacturing, construction, oil and gas industry or another industry.

new importers, sourcing from China is a daunting task. TOBO Alloy 690 tubehigh priority for these importers, especially steel sector. We help our clients in choosing the best suppliers and ensure the quality of their products. also organize for shipping to the port. This makes entire buying process much more secure.

When using alloy 690 tube, its necessary to follow safety guidelines and handle it with care. Always wear protective gear including gloves safety glasses, when working with any metal. Additionally, TOBO GROUP reducing weld neck flange is crucial to work in a well-ventilated area avoid any dust or fumes produced by the metal. Lastly, be sure to properly store the alloy to stop any contamination or damage.

We are invested in providing exceptional provider our customers. We provide high-quality alloy 690 tube, plus the expertise to help our customers find the materials being correct their needs. Our team is unquestionably open to answer any relevant questions or concerns and supply assistance with the higher practices for handling and using TOBO GROUP 2 inch threaded nipple.

Our focus is on providing all the quality materials to our highest customers possible. Our alloy 690 tube was produced making use of the most advanced manufacturing, ensuring consistent quality and gratification. We also have rigorous quality control procedures in spot to make sure that every product meets our high standards.

Copyright © TOBO GROUP All Rights Reserved - Privacy Policy